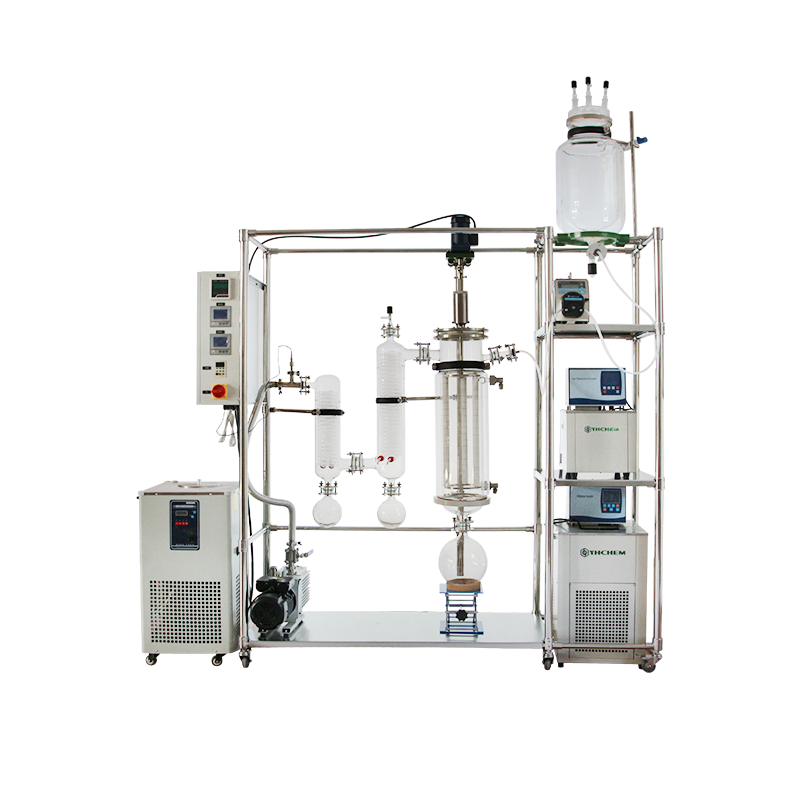

Thin film evaporation system

The main components of the glass thin film distillation system are made of high borosilicate 3.3 material, and the evaporator is made of glass sintering. It is easy to clean without dead corners. At the same time, it reduces the number of interfaces and ensures high vacuum. The experimental materials are completely distilled from feeding to collecting materials. The process is intuitive and visible, and the parameter settings can be adjusted at any time according to the experimental phenomenon, which is convenient to quickly find the best process conditions. High borosilicate glass also has good corrosion resistance, which is an ideal choice for experimental research and development or small-scale production

The glass parts are made of high borosilicate 3.3 material, with excellent visibility;

The magnetic coupling seal can maintain a higher vacuum degree to ensure the evaporation effect;

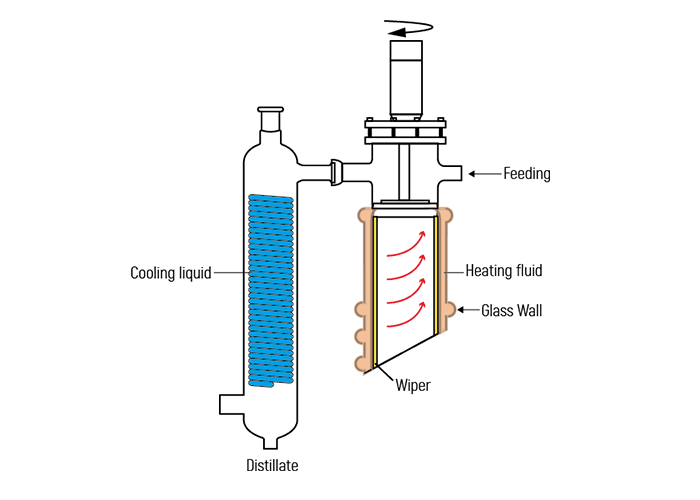

Scraper film forming design, contact material material stainless steel 316L+PTFE;

The sealing ring is made of fluorine rubber or tetrafluoroethylene, suitable for different material applications;

The main evaporator can be designed with full jacket and full insulation to ensure material fluidity;

Digital display Pirani vacuum gauge, accurate feedback of vacuum degree;

Multi-plan structure configuration to guarantee different material and different process requirements;

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support