Phosphoric acid extraction

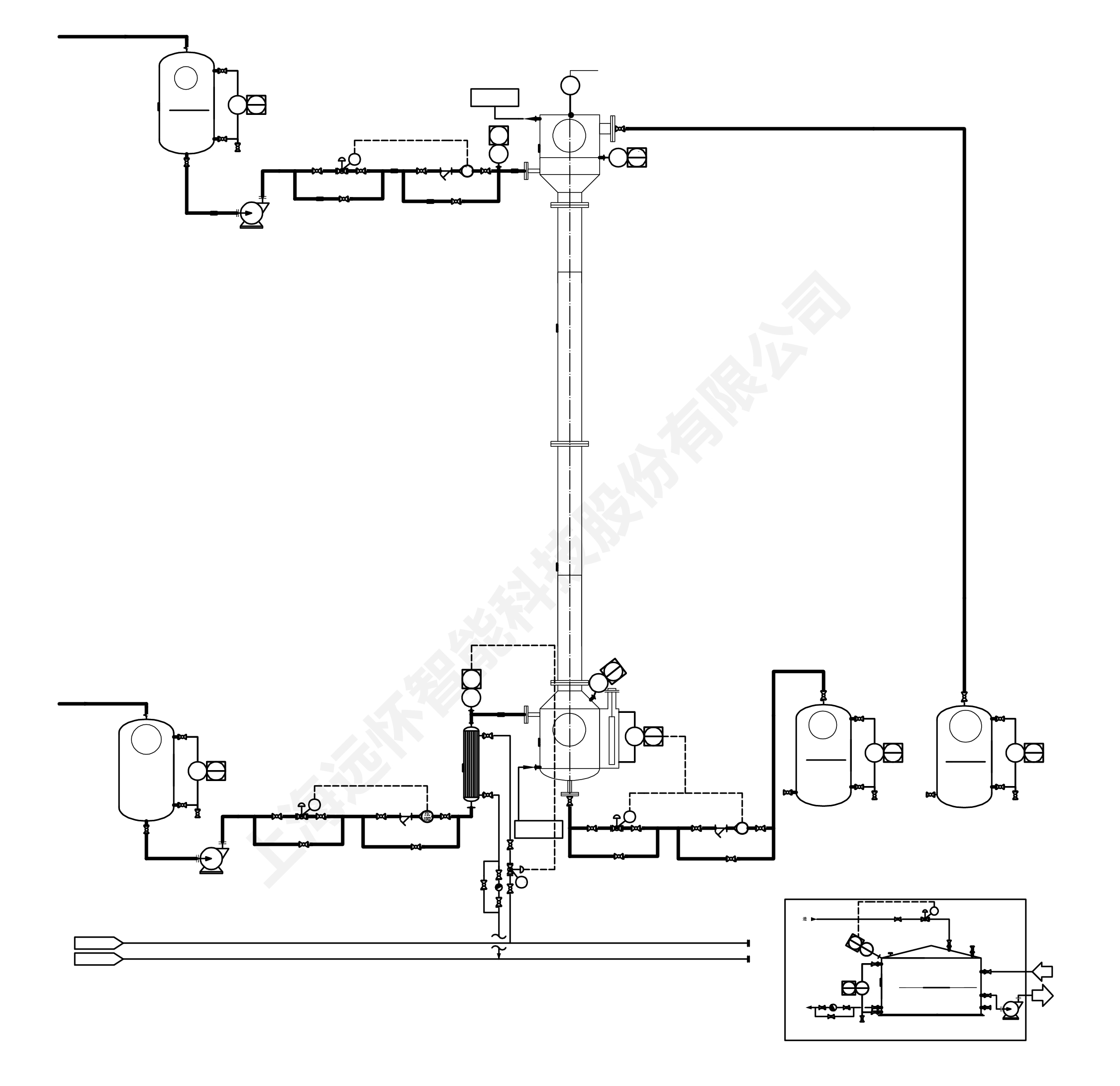

Water phase concentrated phosphoric acid extraction process and core process equipment:

Wet process phosphoric acid filtrate - filtration concentration - reciprocating sieve plate extraction tower TBP extraction - extraction phase concentration

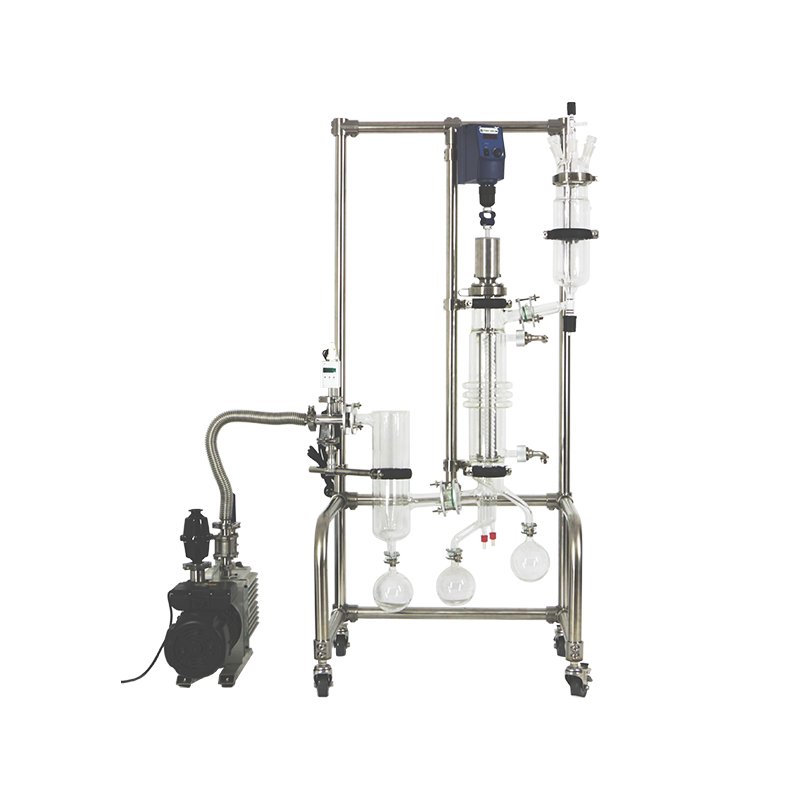

Core equipment: reciprocating sieve plate extraction system

Including reciprocating sieve plate extraction column (RPEC), extraction agent feed preheating heat exchanger, feed liquid storage tank, extraction agent storage tank, extraction liquid storage tank, waste liquid storage tank, automation controller, etc;

The basic structure of RPEC is to install a series of perforated sieve plates on the central axis of the tower. The central axis is driven by the driving mechanism at the top of the tower to perform reciprocating motion. The light phase and heavy phase enter from the bottom and top of the tower respectively. Due to the reciprocating vibration of the tray, the two-phase liquid in countercurrent contact is evenly dispersed, with a large mass transfer area. Then, the light and heavy two-phase liquids are clarified and separated at the top and bottom of the tower, completing the continuous countercurrent extraction process.

Compared with other types of extractors, RPEC is an efficient continuous extraction equipment with external energy, used in liquid-liquid extraction processes, with maximum volumetric efficiency, small amount of extractant, solvent savings, and cost reduction. It is also suitable for materials that are prone to emulsification and impurities. Due to the adjustable parameters of the tower, it is flexible and convenient to operate, and has a wide range of applicability.

Phosphoric acid extraction

Automation control of process flow:

1. Advanced and reliable.

Advanced control systems combined with optimal detection methods ensure the true and reliable detection of temperature, pressure, flow rate, and liquid level during the production process.

2. Easy to operate.

Clear and reasonable pipeline layout combined with systematic training can enable staff to fully master process operations in a short period of time.

3. The safety of the process.

Multi detector cooperation, integrated control, using PLC and human-machine interface for control, centralized control of various adjustable parameters such as feed flow rate, discharge flow rate, temperature, etc.

4. Modular design

Through modular design, it can be directly used for the continuation of front-end processes, and after the design is completed, some equipment can be added or left vacant on the basis of the designed complete set of equipment according to different production situations, achieving efficient utilization of energy and labor, and providing process scalability.