Modified Phenol Aldehyde Resin Adhesive

In 1872, German chemist A. Baryer first synthesized phenolic resin, which was the first artificially synthesized and industrialized polymer compound. Phenolic resin can be divided into solid phenolic resin or liquid phenolic resin according to its morphology, generally colorless or yellow brown. As it is a resin formed by the condensation of phenols (phenol, alkylphenols, etc.) and aldehydes (formaldehyde, mainly) under the action of a catalyst, residual phenols in the material sometimes appear slightly red, and can be formed into thermoplastic or thermosetting resins according to different catalytic processes.

Phenolic resin application industry:

The adhesive industry - mostly uses phenol formaldehyde resin synthesized and catalyzed by alkali, and is also modified with polyvinyl alcohol aldehyde, polyamide, etc. to improve the toughness and adhesion of phenolic resin. It is commonly used in the production of weather resistant and heat-resistant phenolic resin adhesives for wood products. In addition, there are various types of adhesives such as urea modified phenolic resin adhesive, phenolic polyvinyl alcohol aldehyde adhesive, phenolic chloroprene adhesive, etc. At present, the mid to high end market for high-performance reinforced phenolic resins or specialized phenolic resins in China continues to maintain a situation of supply shortage due to high technical barriers and few new entrants.

Modified Phenol Aldehyde Resin Adhesive

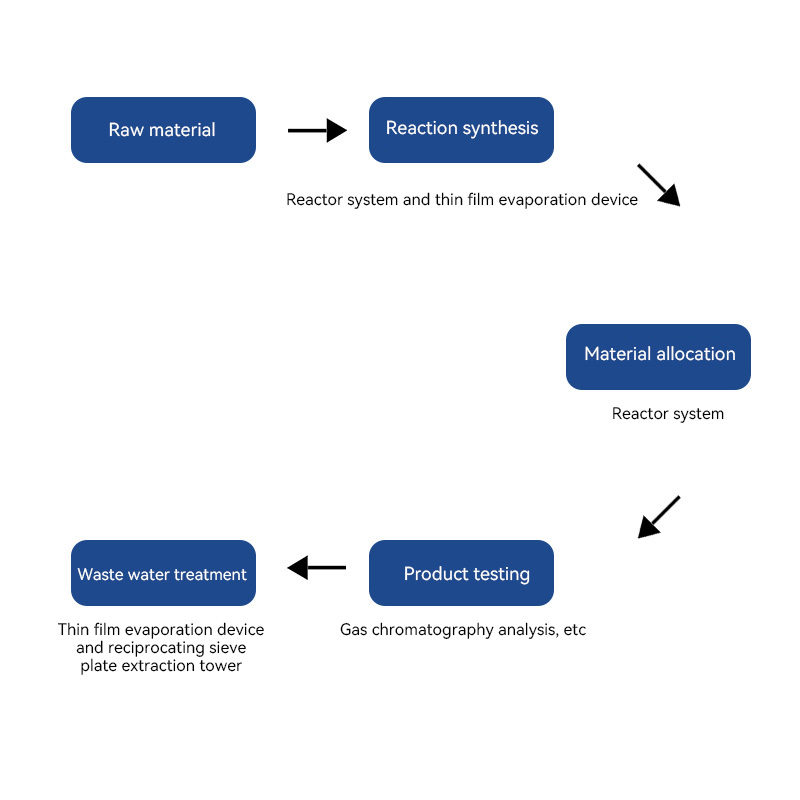

Production process of modified phenolic resin adhesive

Alcohol soluble phenolic resin

In the synthesis process of alcohol soluble phenolic resin adhesive, it is necessary to reduce the pressure and dehydrate after reflux, and then add ethanol as a solvent

phenolic resin

Water soluble phenolic resin adhesive requires the addition of water, phenol, and alkaline catalyst in the early stage of the reaction. Using water as a solvent can not only avoid the harm of organic solvents to the environment and human health, but also reduce the synthesis cost of phenolic resin adhesive.

Barium phenolic resin

Barium phenolic resin adhesive is made by blending acetone or ethanol with petroleum sulfonic acid as a solvent

1. Raw materials - synthetic raw materials for phenolic resins, such as aldehydes, phenols, modifiers, plasticizers, fillers, etc

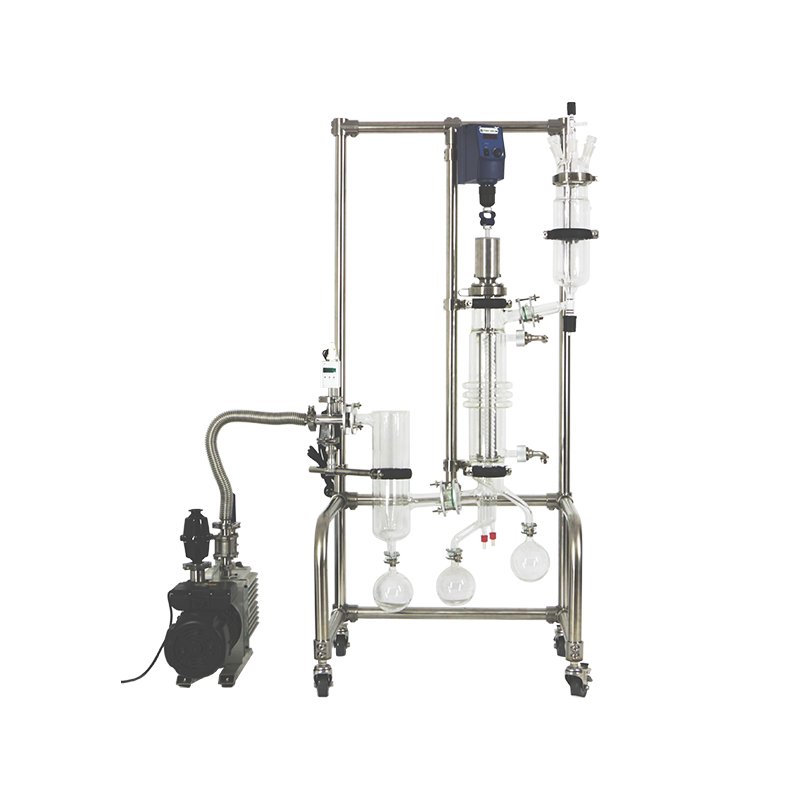

2. Reaction synthesis (reaction kettle system and thin film evaporation device) - In this process, a Far Huai stainless steel reaction kettle system can be configured. The melted phenol and barium hydroxide are manually or automatically controlled according to the ratio and added to the reaction kettle in sequence. Formaldehyde is added under high-efficiency paddle stirring and heated to react. The temperature is maintained at boiling reflux for 1 hour at 95-100 ℃, and then the Far Huai thin film evaporation device is used for vacuum dehydration at 65-70 ℃.

3. Material mixing (reaction kettle system) - When the viscosity reaches 1200~1500cp, it is the end point of the reaction. Then mix plasticizers and fillers according to the ratio and stir evenly. The conventional production process of phenolic resin can be divided into one-step and multi-step methods, and the use of alkali catalysts and modifiers, material feeding time, feeding ratio, heating, insulation, and reflux conditions vary depending on the process.

4. Product testing (gas chromatography analysis, etc.) - Product testing often includes different testing items such as appearance, storage stability testing, flexibility determination, viscosity testing, tensile shear strength, free formaldehyde content determination, thermogravimetric analysis, infrared analysis, gas chromatography analysis, etc.

5. Wastewater treatment (thin film evaporation device and reciprocating sieve plate extraction tower) - In the production process of phenolic resin, a large amount of phenolic resin wastewater is generated in each section. Depending on the production process and operating conditions, the composition and concentration of the wastewater produced also vary. The main substances in the wastewater are phenols, aldehydes, and alcohols. The Yuanhuai membrane system can be used to quickly remove a large amount of light organic toxic substances from wastewater, and the Yuanhuai reciprocating sieve plate extraction tower can be used to recover economical materials such as phenols.