Fish oil extraction

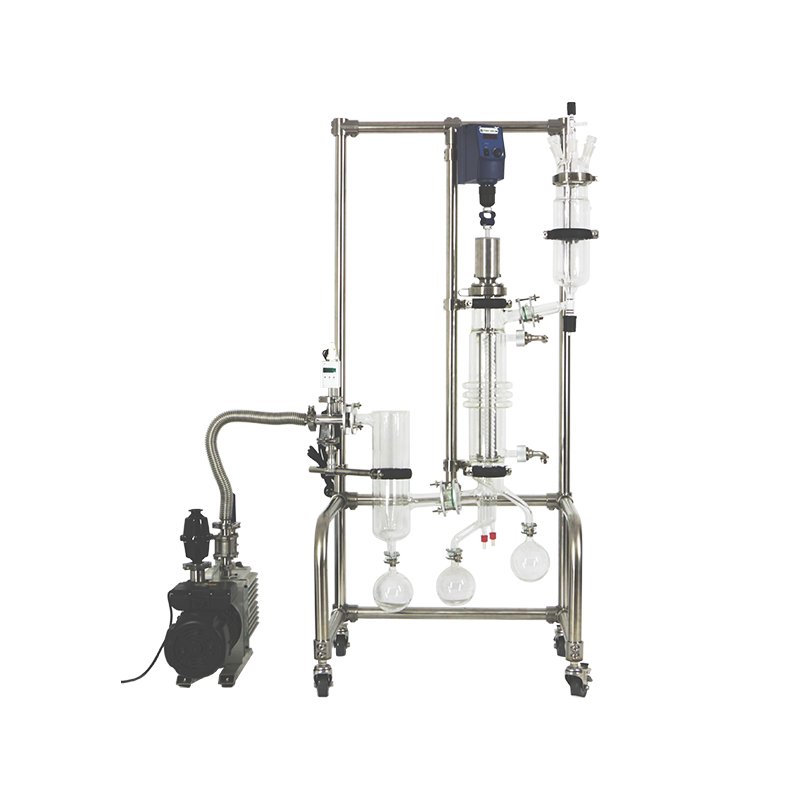

Deep sea fish oil is a natural health supplement with high nutritional value. It is rich in high unsaturated fatty acids, with typical representatives being eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) in omega-3 unsaturated fatty acids; Modern medicine has proved that EPA and DHA have important physiological functions such as reducing blood fat and cholesterol, promoting brain nerve and retinal development, anti epilepsy, arrhythmia, preventing vascular fibrosis, and can effectively prevent and control certain diseases, such as hypertension, heart disease, cancer, and diabetes. At present, the extraction methods widely used in industry are mainly freeze crystallization and urea encapsulation, which have the disadvantages of low extraction rates and solvent residue problems. Yuanhuai provides various solutions such as distillation and rectification, which can achieve purification of fish oil with different purities.

Fish oil extraction

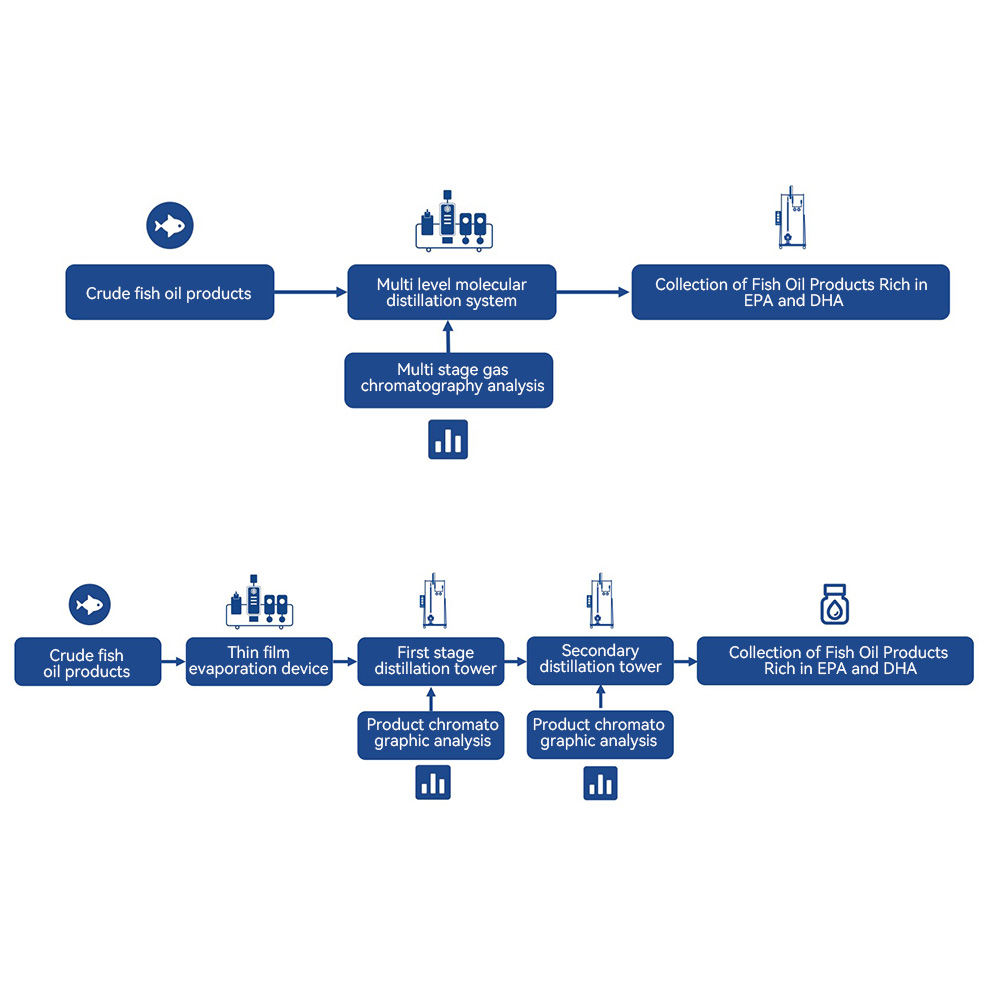

1. Recommended process flow for fish oil production: In this process, crude fish oil products are used as raw materials, and a molecular distillation device is customized based on the content and amount of feed components. The light phase impurities are removed through multi-stage molecular distillation. As the molecular distillation stage increases, the EPA content in the light phase increases, and the DHA content in the heavy phase increases. After reaching the target concentration, the light phase and heavy phase products are collected. During the production control process, gas chromatography is used for real-time content analysis and detection of fish oil products to ensure production quality.

2. Recommended process flow for fish oil production 2: In this process, crude fish oil products are used as feed raw materials. Through customized design of feed component content and feed amount, the thin film evaporation device removes impurities of light components below carbon 18, and the heavy phase enters the first distillation tower to further remove low content short carbon chain components. The first distillation tower separates multiple unsaturated fatty acid heavy phases rich in EPA and DHA, and real-time and accurate purity monitoring of the heavy phase is carried out using gas chromatography. Subsequently, the heavy phase of the first distillation enters the second distillation tower, where EPA and DHA are separated according to production requirements. At the same time, gas chromatography analysis is performed on the light and heavy phase discharges to confirm that the target purity has been achieved, and product collection is completed in the light and heavy phases.

(More precise process routes can be customized according to different materials to be processed)