Short path distillation kit

Short path distillation is a distillation technique that involves the distillate travelling a short distance. It is method of separating mixtures based on differences in their volatilities in a boiling liquid mixture under reduced pressure. As the sample mixture to be purified is heated, its vapors rise a short distance into a vertical condenser where they are cooled by water. This technique is used for compounds which are unstable at high temperatures because it allows a lower boiling temperature to be used.

The glass parts are made of high borosilicate 3.3 material, with excellent visibility;

Short condensing distance and few residue left after evaporation;

The reflux design improves the evaporation efficiency;

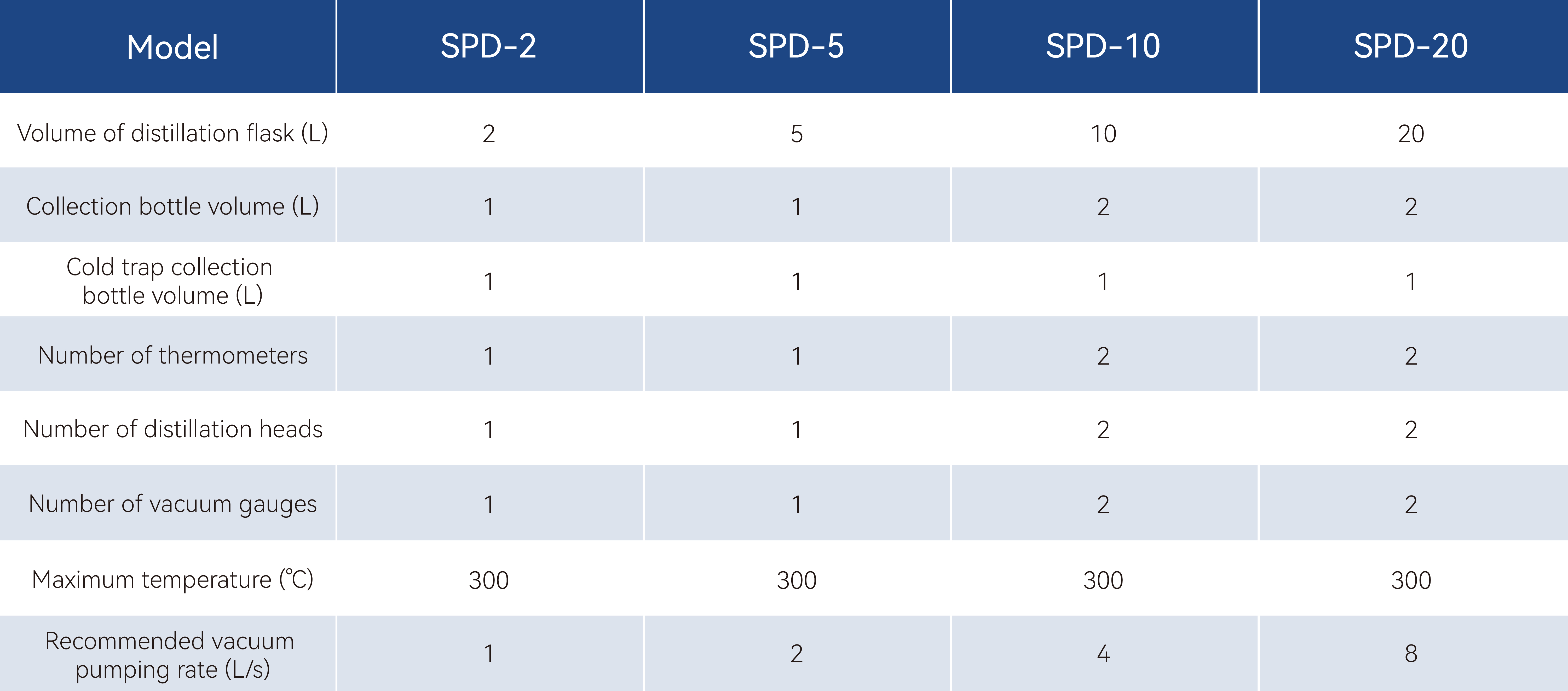

The highest heating temperature is 300℃, with optional magnetic stirring function;

The minimum operating vacuum is less than 0.1mbar, which significantly reduces the evaporation temperature;

Material handling capacity: 0.05-5Kg/h (according to specific materials), easy to operate;

.jpg)

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support