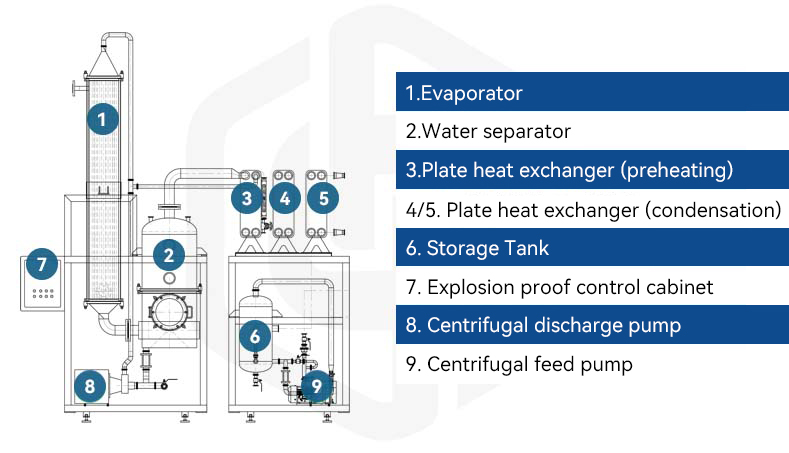

Falling film evaporator

The falling film evaporator is to add the liquid from the heat exchanger, through the liquid distribution and film forming device, evenly distributed into each heat exchange tube, under the action of gravity, vacuum induction and air flow, it becomes a uniform film flow down from the top. During the flow process, it is heated and vaporized by the heating medium in the shell side, and the generated vapor and liquid phase enter the separation chamber of the evaporator together. After the vapor-liquid is fully separated, the vapor enters the condenser to be condensed and collected. Falling film evaporators are mainly used in solvent recovery in biological, pharmaceutical, chemical and other industries, and can be used in multiple stages to achieve a higher energy efficiency ratio.

Falling film evaporator is production distillation equipment

Modular design, flexible selection;

The material is uniformly distributed and the heat exchanger utilization rate is high;

Cyclone gas-liquid separation design reduces material loss;

Forced circulation of roller flow pump to increase material concentration;

The ultimate vacuum is lower than 50mbar, which is good to reduce energy consumption;

Certification:CE

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support