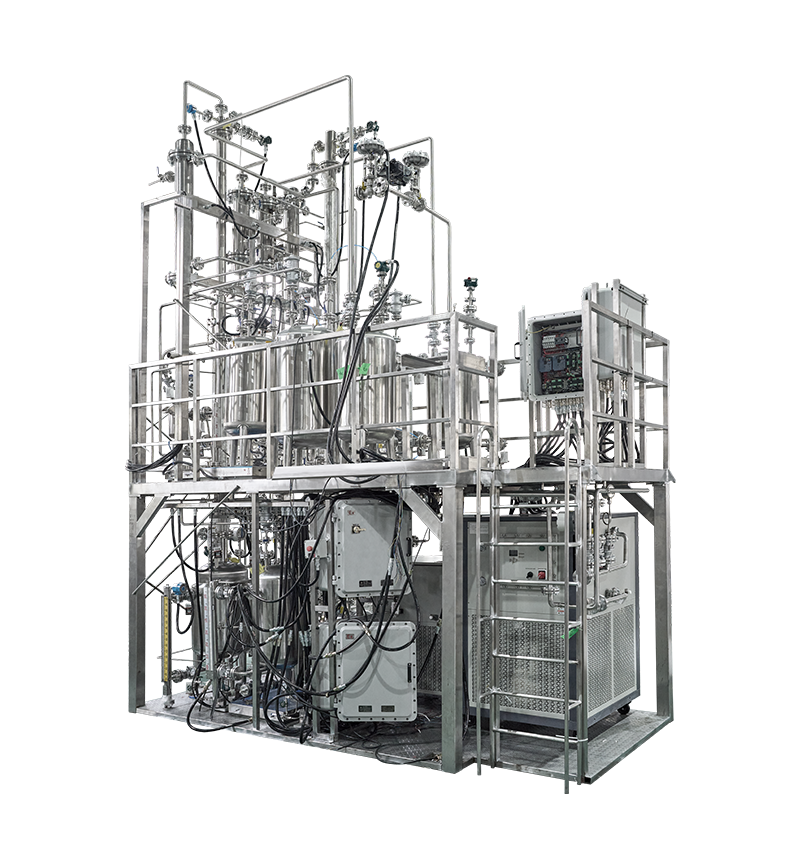

Stainless steel distillation column

Using the different volatility of each component in the mixture, that is, the vapor pressure of each component at the same temperature has different properties, the light components in the liquid phase are transferred to the gas phase, and the recombination components in the gas phase are transferred to the liquid phase, and the gas-liquid mixture undergoes multiple phase vaporization and phase condensation when flowing through the filler, so that the concentration of the light components in the gas phase and the recombinant components in the liquid phase gradually increases, so as to achieve the purpose of separation.

Modular design for easy conversion of batch distillation mode to continuous distillation mode;

The heat transfer oil is heated, and the temperature inside the tower kettle is uniform and stable;

Magnetic seal structure for high vacuum rectification;

The reboiler can choose a thin film evaporator, which has a very good protection effect on heat-sensitive and easily oxidized materials;

The contact material part is all made of SUS316L steel, or other corrosion-resistant materials can be customized;

The tower column adopts multi-stage temperature control (or insulation) interface to meet various process requirements;

Optional gear pump, more stable material transfer;

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support