Temperature Control System

The TCU temperature control system is mainly a refrigeration, heating, and temperature control equipment used for controlling the temperature of multiple reactors. It can be used to achieve the refrigeration, heating, constant temperature, and evaporation processes of the reactors, such as sulfurization, nitrification, hydrogenation, alkylation, polymerization, and condensation. The TCU temperature control system is a device that controls the temperature of multiple reactors through multiple programs. It quickly heats or cools the jacket volume of the reactors to meet the required temperature range. There are many models of TCU temperature control systems, with multiple choices of large, medium, and small sizes. Reasonable configuration of various internal components and external auxiliary components makes it easy to operate, good heat dissipation, efficient cooling, and quiet operation.

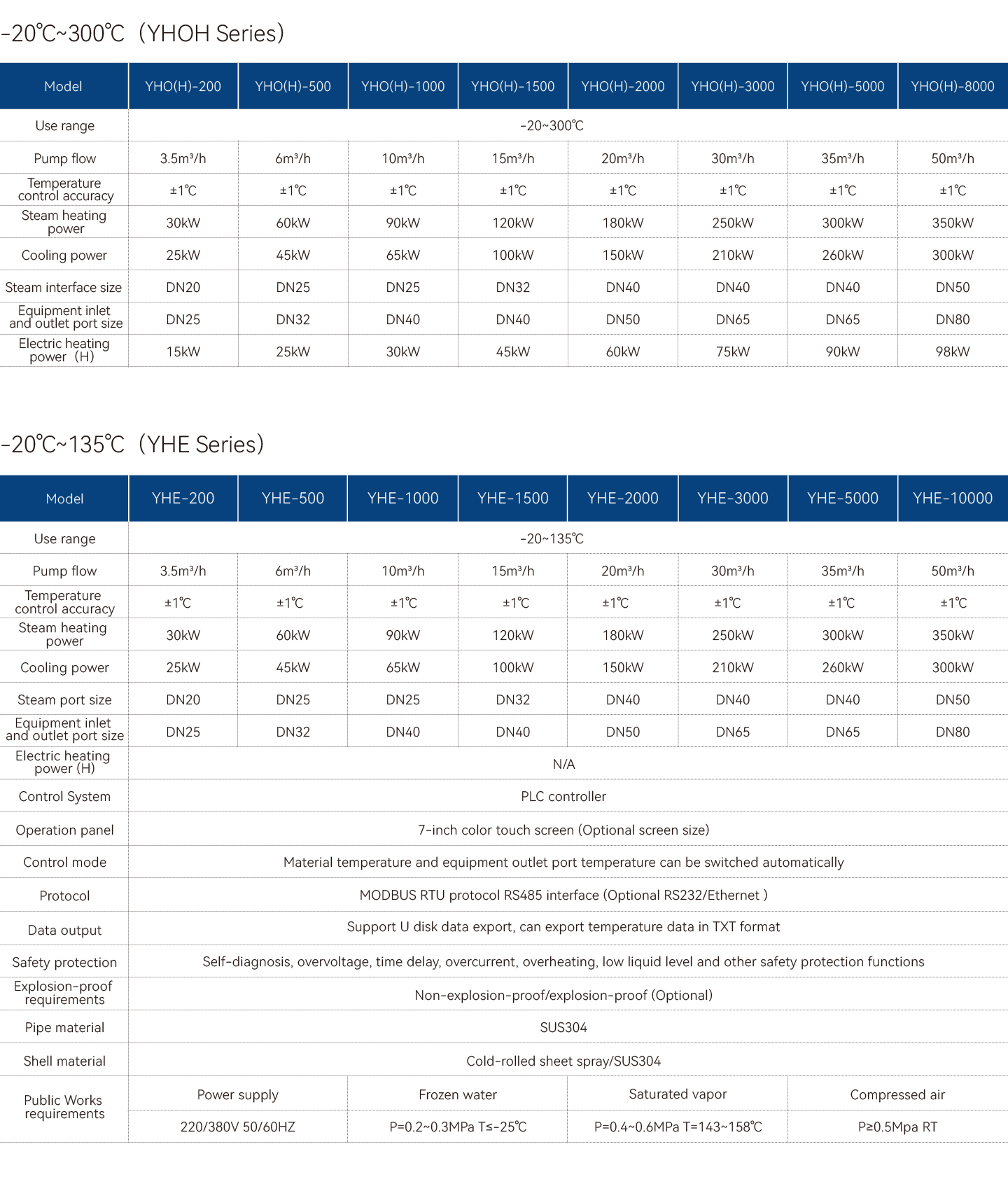

Users can obtain a closed and repeatable temperature control within a wide temperature range, achieving -20℃~300℃ temperature control

Avoiding the need for replacement and jacket maintenance of traditional equipment and facilities: the small fluid volume also ensures fast response of the control circuit and minimal thermal reaction delay

Built in electric heating heat transfer oil auxiliary system, which can automatically start the auxiliary heating system according to demand, reducing steam usage pressure

By quickly and accurately matching various heat demands, energy conservation can be achieved

The temperature of the whole reaction process is controlled through fast calculation, and fast response control is carried out for the exothermic and endothermic reaction in the whole reaction process

Standardized interfaces are reserved, and cold and heat source heat exchange modules can be added according to actual needs

The reaction process temperature and single fluid temperature can be selected for control, and the temperature difference between the reaction process temperature and the thermal conductivity single fluid temperature can be set and controlled

Built in various winding heat exchangers, made of stainless steel, resistant to corrosion, high pressure, scaling, and high heat exchange efficiency

Adopting a fully enclosed pipeline design for formula management and production process recording

Using the system feedback temperature as the signal source, the controller calculates and provides the action command of the electric control valve to control the flow rate of low-temperature liquid entering the reactor jacket, thereby achieving efficient control

Fish Oil

The crude fish oil is esterified, washed and dehydrated to obtain fish oil and ethyl ester.

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support