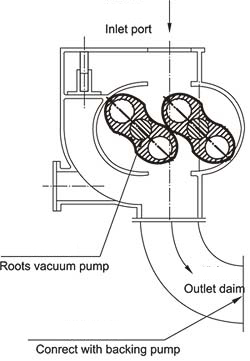

Roots vacuum pump (low noise series)

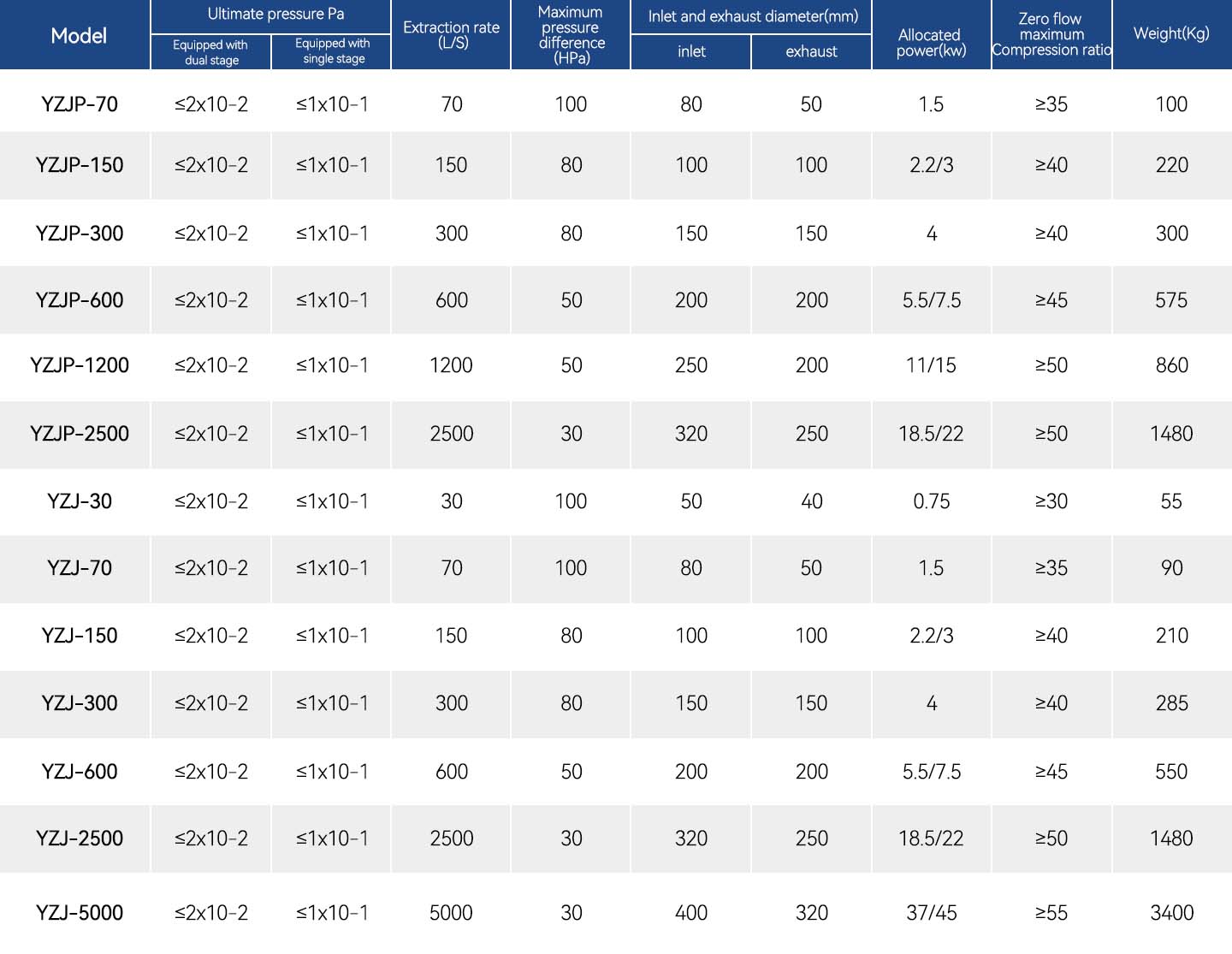

The Roots pump mainly consists of a pair of synchronous high-speed rotating "8" shaped rotors and two semi circular pump cavities. This pump cannot exhaust independently and must be used in series with the front stage pumps (such as slide valve pumps, rotary vane pumps, water ring pumps, oil ring pumps, etc.). Connecting a Roots vacuum pump in series in front of the inlet of the front stage pump can improve the vacuum degree of the front stage pump and greatly increase the pumping rate within an effective range. The limit pressure of the Roots vacuum pump is determined by the front stage pump, and the data in the table is the minimum limit pressure for the standard configuration (equipped with a dual stage oil seal mechanical vacuum pump). Roots pumps are widely used in vacuum casting, vacuum melting, vacuum degassing, vacuum coating industry, Vacuum distillation and vacuum drying in chemical and pharmaceutical industries. The pump is not sensitive to small amounts of dust.

Smooth operation, low noise, low vibration, and high limit vacuum.

Due to the reliable clearance elimination structure adopted by the transmission components of the pump, the pump can operate for a long time under high pressure difference.

Fast start, able to reach the maximum vacuum in a short period of time.

Due to the absence of sliding parts in the pump chamber, there is no need for oil lubrication to avoid contamination of the system by oil vapor.

Safe and reliable, the ZJP series is equipped with an overflow valve for automatic protection.

Compact structure and small footprint. You can choose any of the three exhaust ports on the left, right, and bottom for easy installation by users

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support