Single Layer Reactor(SS)

YHChem stainless steel reactor is a chemical reaction vessel of stainless steel. It is composed of four parts: the inner vessel, jacket, stirring device, and supporting frame, participate in the completion of vulcanization, nitrification, hydrogenation, alkylation, polymerization, condensation and other processes, in order to participate in the intensive mixing of reactive substances as the premise, for heating, cooling, and liquid extraction and gas absorption and other physical changes using stirring device to achieve good results. It has the characteristics of rapid heating, high temperature resistance, corrosion resistance, health and easy to use.

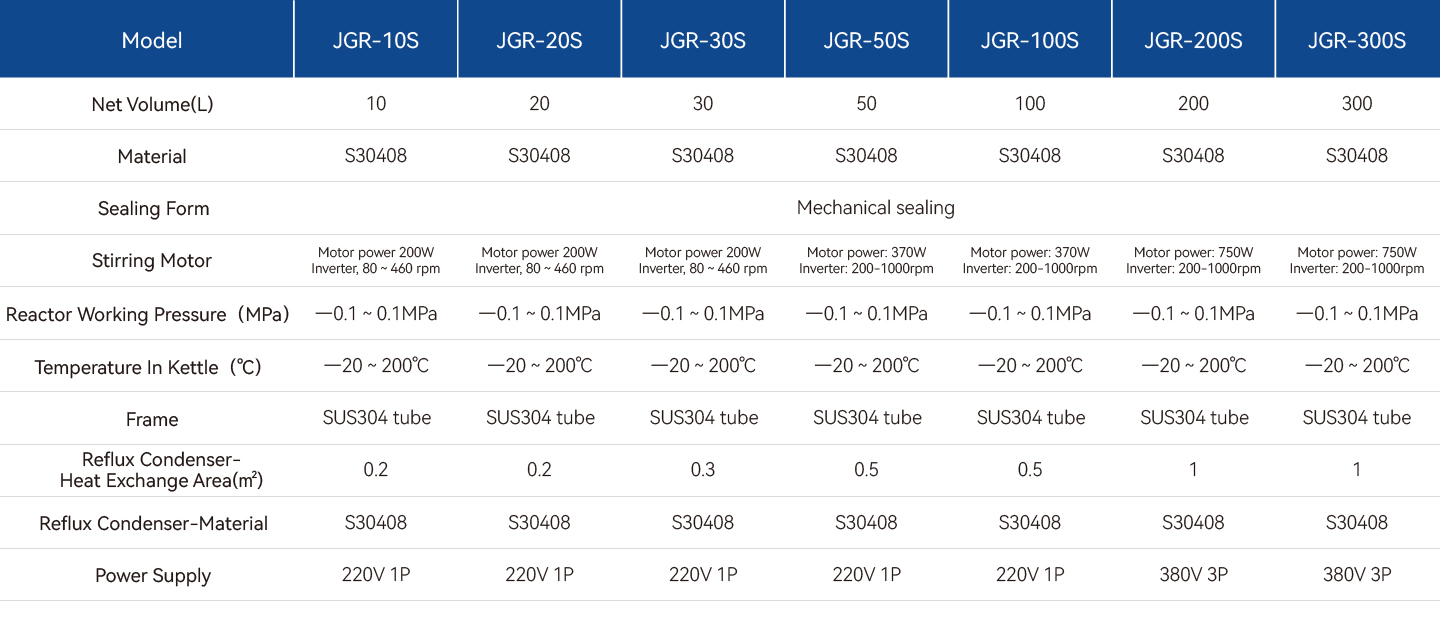

YHChem supplies various of stainless steel jacketed reactor from 20L to 300L. and the reactor can be used with heating/cooling circulator, cooling chiller, water cycle vacuum pump, etc.

The vessel is made of stainless steel SUS304 according to the process, and the inner surface is polished to make it safer to use

The stirring motor has the function of frequency conversion speed regulation, meeting the high and low speed requirement.

Skid mounted design makes the equipment easier to disassemble and move, greatly enhanced flexibility

Digital Display Speed Controller,Intuitively understand the temperature change in the kettle

Mechanical Seal,Ensure the vacuum environment in the reactor

The jacket interface could connected with thermal oil for heating reaction or refrigerant for low temperature reaction.

Support customization service

24-hour professional consulting service

On site installation training services

24/7 service

Professional process training

2 R&D centers

Experienced Chinese and American researchers

Multiple cooperative universities with cutting-edge technology support